- Published: 08 May 2019

- Written by Editor

Osisko Metals Announces Successful Material Sorting Results at Pine Point

Osisko Metals Announces Successful Material Sorting Results at Pine Point

For Dense Media Separation (“DMS”):

- Zinc recoveries ranged from 76.7% to 96.2% (average of 92.4%)

- Lead recoveries ranged from 87.4% to 98.7% (average of 95.3%)

- Mass pull* ranged from 12.8% to 61.5% (average of 30.4%)

- Average grade of rejected material is 0.75% Zn and 0.08% Pb

* Mass pull is a measure of the weight percentage of material mass recovered from the pre-concentration test, hence the smaller the number the higher the savings in transportation costs and processing volume to the projected mill.

Results indicate similar recoveries for both processes, but XRT is the preferred process as the end product is expected to be dry and easier to handle in northern weather conditions. Furthermore, machinery necessary for near-pit XRT sorting is also more mobile than DMS equipment, providing more operational flexibility to the future operation.

Jeff Hussey, P. Geo., Osisko Metals President and CEO, stated: “This round of test work expands upon previous material sorting studies and conclusively confirms Pine Point material is amenable to XRT pre-concentration. Indications are that roughly half of the waste rock material can be rejected near potential pit operations with less than 10 percent loss of both zinc and lead mineralization. The benefits of incorporating a pre-concentration process at Pine Point would be to significantly reduce haulage costs and reduce the material throughput in the mill. Based on the combination of these benefits, project economics would improve from substantial operating and capital cost savings.”

Mr. Hussey continued: “One of the key benefits of the Pine Point project is the proven high metal recoveries using conventional flotation. Historical results from the Cominco Ltd. era highlight that there is negligible deleterious elemental content and high recoveries for both the zinc and lead concentrates. We believe Osisko Metals is well positioned to leverage both this excellent response to preconcentration techniques and the premium quality of potential production of Pine Point concentrates.”

Pre-concentration Test Work Details

Two pre-concentration processes were evaluated: X-Ray Transmission material sorting and Dense Media Separation. The two processes rely on the significant density contrast between the sulphide material, composed of sphalerite and galena, and the barren dolomitic limestone waste rock. XRT is a dry process (opposed to the “wet” process of DMS) whereby crushed material is fed along a wide conveyor belt, analyzed by X-Ray to sort the materials before air jets are deployed to reject waste rock particles. DMS uses a liquid with a set density to separate sulphide material, which sinks, from waste material which floats on the liquid. Both processes greatly reduce the material to be handled and processed in the concentrator following pre-concentration, either method could further improve future project economics and operational benefits.

The pre-concentration test work was performed on a composited total of 800kg of representative Pine Point mineralized drill core samples from the summer 2017 and winter 2018 drilling campaign. Four separate head samples were prepared from this material and are listed below:

- 200 Kg of High-Grade Range: Averaging 15% Zn & 6% Pb

- 200 Kg of Medium-High Grade Range: Averaging 10-15% Zn & 3% Pb

- 200 Kg of Average Grade Range: 5% Zn & 2% Pb

- 200 Kg of Low-Grade Range: 2% Zn & 1% Pb

From these head samples, sub-samples were composited to cover a wider range of potential mill feed grade combinations. The prepared sub-samples were used to measure the response to potential grade variability throughout the project’s various mineralized zones. Sub-sample mill feed grade ranges are listed below (LOM = life of Mine):

| Sample | Pb | Zn | ||

| % | % | |||

| LOM Low Grade | 0.7 | 3.19 | ||

| LOM | 1.12 | 4.56 | ||

| LOM Medium Grade | 1.11 | 6.16 | ||

| LOM High Grade | 2.47 | 11.34 |

| Sample | Pb | Zn | ||

| % | % | |||

| Low Grade | 0.5 | 1.97 | ||

| Medium Grade - Low Grade | 1.01 | 4.95 | ||

| Medium Grade | 1.31 | 7.28 | ||

| High Grade - Low Grade | 2.43 | 8.84 | ||

| High Grade - Medium Grade | 3.32 | 11.35 | ||

| High Grade | 4.77 | 16.34 |

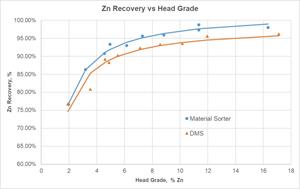

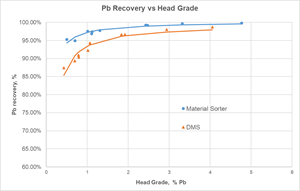

Metal recovery and mass pull were strongly linked to head grade in both the XRT and DMS results (summarized in the chart below).

Two charts accompanying this announcement are available at

http://www.globenewswire.com/NewsRoom/AttachmentNg/0eea38c3-0aaf-4a09-8f62-b6379daaf5dc

http://www.globenewswire.com/NewsRoom/AttachmentNg/857a06c9-4050-4356-9dd9-026565152d9f

X-Ray Transmission Material Sorting (XRT)

The material was prepared by hand in order to have a particle size range between -60mm and +10mm. Coarser particles were broken using a hammer and finer particles were removed using screens and stored.

The material sorter test work was performed at Steinert’s testing facility in Kentucky, USA. Several sensors were tested to investigate which technology would have the best response to Pine Point material. X-ray transmission sensors, which measure the density of the sample, were the most efficient at sorting mineralized material from barren host rock. If particles have a density that resembles limestone, they are rejected. The “mass pull” is the percentage of feed material that is recovered, or having a density that is typical of sulphide mineralization.

Dense Media Separation (DMS)

The XRT material sorter sample material was recombined with the fines before it was split. Half was sent for flotation test work and the other half was shipped to SGS laboratory in Lakefield for the Dense Media Separation test work. A dense media liquid with a density of 2.9 grams per cubic centimeter was used for the DMS test work.

Ongoing Flotation Test Work

Cominco Ltd.’s historical production records (from 1975 to 1988) list a weighted average zinc recovery of 91.91% for a head grade of 6.54% zinc, producing a concentrate grade of 58% zinc. The lead recovery averaged 88.69% for a head grade of 2.56% lead, producing a concentrate grading 75.68% lead. (Pine Point historical production data reported by R. Silke, 2009).

One “rougher” or first float phase kinetic test was performed on each of the fourteen XRT Material Sorter concentrates to confirm that similar metal recoveries can be achieved as those listed in the historical records. The results from the test work have been partially received and are encouraging. Optimization results will be available shortly, and a complete flotation test work campaign is planned later this year to optimize recovery and operating parameters that would be closer to a full-scale concentrator performance forecast.

About Osisko Metals

Osisko Metals is a Canadian exploration and development company creating value in the base metal space with a focus on zinc mineral assets. The Company controls Canada’s two premier historical zinc mining camps: The Pine Point Mining Camp (“PPMC”), located on the south shore of Great Slave Lake in the Northwest Territories, near established infrastructure, paved highway access and with 100 kilometres of mine haulage roads and power substation already in place. The PPMC currently hosts a NI43-101 Inferred Mineral Resource of 38.4 Mt grading 4.58% zinc and 1.85% lead, making it the largest near-surface, pit-constrained zinc deposit in Canada (please refer to the SEDAR-filed Amended Technical Report for further information). The 2018-2019 drill holes, once fully assayed, will be incorporated into the database with the objective of issuing a new resource estimate in H2 2019. The Bathurst Mining Camp (“BMC”), located in northern New Brunswick, with NI43-101 Indicated Mineral Resources of 1.96 Mt grading 5.77% zinc, 2.38% lead, 0.22% copper and 68.9g/t silver (9.00% ZnEq) and Inferred Mineral Resources of 3.85 Mt grading 5.34% zinc, 1.49% lead, 0.32% copper and 47.7 g/t silver (7.96% ZnEq) in the Key Anacon and Gilmour South deposits. In Québec, the Company owns 42,000 hectares that cover 12 grass-root Zinc targets that will be selectively advanced through exploration in 2019.

Technical Information, QA/QC and Qualified Persons

Metallurgical program design, monitoring and sample preparation were completed under the supervision of Mr. Christian Laroche, P. Eng. and Mr. Robin Adair, P.Geo., both Qualified Persons as defined by National Instrument 43-101.

Metallurgical testing and analyses were performed at Steinert US Inc. in Walton Kentucky, SGS Mineral Services in Burnaby, British-Columbia and SGS Lakefield in Ontario, Canada. The QA/QC program utilized is consistent with NI 43-101 and industry best practice standards. This news release was reviewed and approved by Mr. Laroche and Mr. Clemmer.

| For further information on Osisko Metals, visit www.osiskometals.com or contact: | |

|

Jeff Hussey President & CEO Osisko Metals Incorporated (514) 861-4441 Email: This email address is being protected from spambots. You need JavaScript enabled to view it. www.osiskometals.com |

Christina Lalli Director, Investor Relations Osisko Metals Incorporated (438) 399-8665 Email: This email address is being protected from spambots. You need JavaScript enabled to view it. www.osiskometals.com |

Cautionary Note Regarding Forward-Looking Information

This news release contains "forward-looking information" within the meaning of applicable Canadian securities legislation based on expectations, estimates and projections as at the date of this news release. Forward-looking information involves risks, uncertainties and other factors that could cause actual events, results, performance, prospects and opportunities to differ materially from those expressed or implied by such forward-looking information. Forward-looking information in this news release includes, but is not limited to, the use of proceeds of the Offering; the timing and ability of the Corporation, if at all, to obtain final approval of the Offering from the TSX Venture Exchange; an exemption being available under MI 61-101 and Policy 5.9 of the TSX Venture Exchange from the minority shareholder approval and valuation requirements for each related party transaction; objectives, goals or future plans; statements regarding exploration results and exploration plans. Factors that could cause actual results to differ materially from such forward-looking information include, but are not limited to, capital and operating costs varying significantly from estimates; the preliminary nature of metallurgical test results; delays in obtaining or failures to obtain required governmental, environmental or other project approvals; uncertainties relating to the availability and costs of financing needed in the future; changes in equity markets; inflation; fluctuations in commodity prices; delays in the development of projects; the other risks involved in the mineral exploration and development industry; and those risks set out in the Corporation's public documents filed on SEDAR at www.sedar.com. Although the Corporation believes that the assumptions and factors used in preparing the forward-looking information in this news release are reasonable, undue reliance should not be placed on such information, which only applies as of the date of this news release, and no assurance can be given that such events will occur in the disclosed time frames or at all. The Corporation disclaims any intention or obligation to update or revise any forward-looking information, whether as a result of new information, future events or otherwise, other than as required by law.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this news release. No stock exchange, securities commission or other regulatory authority has approved or disapproved the information contained herein.

Zn Recovery vs Head Grade

Pb Recovery vs Head Grade